by Brian Hampton

Being a CL stunt flier and having a preference for rear exhaust engines I simply HAD to get one. The bad news was that Enya had sold out of them but a little internet searching turned up Randy Smith of Aero Products in America who had them in stock. The matching Enya muffler and stub adaptor weren’t available but Randy had his own header and CNC slip on tubular muffler so they were ordered with the engine. The header shown is full length but will be shortened somewhat when installed in a model. The muffler slides on over the header using an “O” ring for a seal at the front so the rear of the muffler needs to be supported by a clamp.

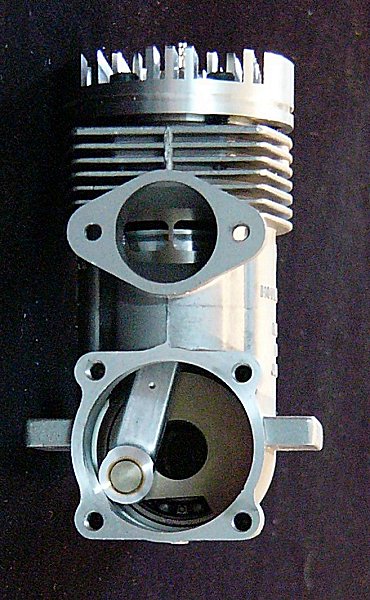

The cylinder head appears to be a normal head with the plug threads machined into the aluminium but appearances can be deceptive. The head is actually a 2 piece like a Rossi with a head button for the combustion chamber and the finned outer clamp ring. As can be seen in the photo, there’s a small dimple on top of the button that’s visible when the head is assembled and at first I couldn’t see the reason for it. I eventually discovered that there’s an optional high compression button (which I believe is standard on the RC version) so the dimple is likely to be a distinguishing mark. The threaded length for the plug exactly suits the medium length Enya (and OS) glow plugs so for a standard long length plug (as I used when running in) an extra washer is desireable although not totally necessary. No shim is used although it’s an optional extra.

Enya in their wisdom, knowing that modellers are always pulling engines apart, have included in the instruction sheet a tightening sequence when refitting the head. This is a first for a manufacturer to my knowledge. Additionally they’ve put a dimple on the rear face of the conrod and specifically state that this is the only way the rod can be fitted correctly. This is common for almost all rods but has caught out many of the unwary who haven’t noticed the tiny chamfer on one end of the rod bush that must fit against the radius ground on the crankpin where it meets the crankweb. The photo shows the dimple and the single normal ring on the piston.

As usual with a new engine, I partly stripped it mainly to record some details of its design.

Bore 25mm

Stroke 20.4mm

Swept volume 10.01cc (0.611 cub inch)

Squish clearance .78mm (.031″)

Combustion chamber volume .96cc

Total combustion chamber volume (total of head and squish volumes) 1.34cc

Compression ratio 8.46:1

Exhaust opens 73 degrees BBDC

Transfer 62 BBDC

Boost 59 BBDC

Inlet opens 40 ABDC

Inlet closes 55 ATDC

Weight without muffler 328 grams (11.56 ounces)

Weight with header and muffler 394 grams (13.9 ounces)

Venturi bore 7.5mm

Spray bar diameter 4mm

Effective Venturi area (bore less spray bar area) 13.87 sq mm (.021 sq inch) but an 8mm venturi will increase the effective area to 18.27 sq mm.

Ratio of venturi area to engine size .035 (that’ll only make sense to a CL stunt flier but it’s an indication of fuel draw) or .46 with an 8mm venturi.